Downhole Tool Design

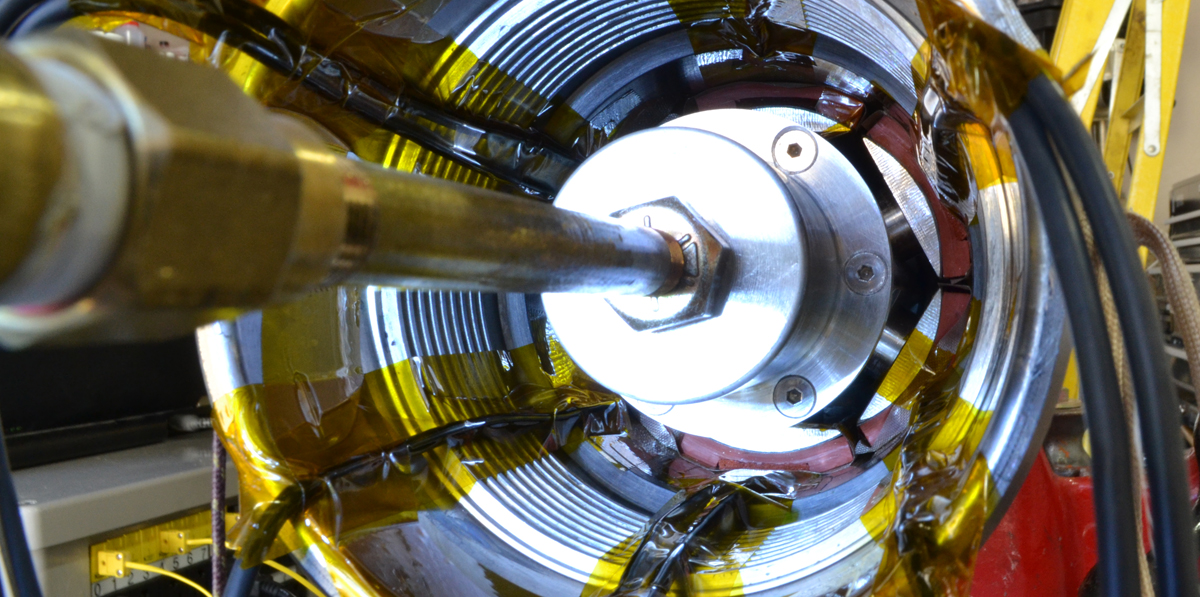

Sensors that measure wellbore pressure during perforation events are normally placed some distance above the perforation guns in order to protect them from the shock of explosive energy release. Engenya collaborated with its partners to design and develop a downhole acceleration, pressure, temperature and force sensing tool that could be placed between loaded perforation guns.

Engenya’s contribution to this project consisted of design support on a multi-disciplinary level, using advanced analysis and simulation techniques ranging from the analysis of stress propagation through the sensor tool resulting from shock loading, to the numerical testing of sensor mounting concepts.

Protection of the electronics was developed through the simulation of drop tests aimed at characterizing the system response in a shock environment. Pressure and other sensor mounting approaches were designed and tested through numerical testing using representative loading spectra. Accelerator sensor mounting dynamics were tuned using modal analysis to evaluate system natural frequencies. Finally, a pressure balanced sensor mount was evaluated using transient dynamic analysis.

This tool enabled, for the first time in the industry, the direct and reliable measurement of perforation dynamics, loads and temperatures within the perforation interval.

Tool characteristics:

– Records multiple events in non-volatile memory.

– Channels: 12.

– Recording frequency: 100 kHz.

– Records dynamic loads including shock, wellbore pressure and local acceleration.

– Records entire job history at a lower rate.